HXELAB (Huaxia Energy) is an industrial company active in the bioenergy

and sustainable fuels industry, with a focus on Sustainable Aviation Fuel (SAF)

and renewable diesel (RD/HVO).

A subsidiary of Eurasia Group (Switzerland), HXELAB acts as an industrial,

commercial and technical partner for international energy companies,

refiners, traders, EPC contractors and investors.

HXELAB combines:

- SAF and RD offtake structuring and trade execution,

- engineering and industrial project development,

- advanced hydrogenation technologies (MCT / HSBH, fixed bed, hybrid schemes).

Supply Chain Structuring and Commercial Interface

HXELAB provides supply chain structuring and commercial interface services

between Chinese industrial producers and international energy groups, traders, and end-users.

Acting as a single industrial and contractual interface, HXELAB supports:

- alignment of production capacities with international demand,

- structuring and arbitration of volumes between domestic and export markets,

- optimization of logistics, storage, and delivery routes,

- management of commercial terms, including pricing structures, sustainability requirements,

and payment mechanisms such as letters of credit.

By combining process knowledge, market visibility, and contractual execution, HXELAB

reduces supply-chain friction and ensures reliable, compliant, and economically optimized SAF and

RD supply flows between China and international markets.

Investment Coordination and Infrastructure Development

HXELAB supports the coordination of investments and the development

of industrial SAF and renewable diesel infrastructure.

The company acts as an industrial integrator, aligning technology selection,

feedstock availability, market demand, and financing to deliver bankable, long-life assets.

HXELAB coordinates technology providers, EPC contractors, industrial partners, and investors,

supporting project structuring, infrastructure definition, and cross-border investment execution

between Chinese and international stakeholders.

Advanced Feedstock

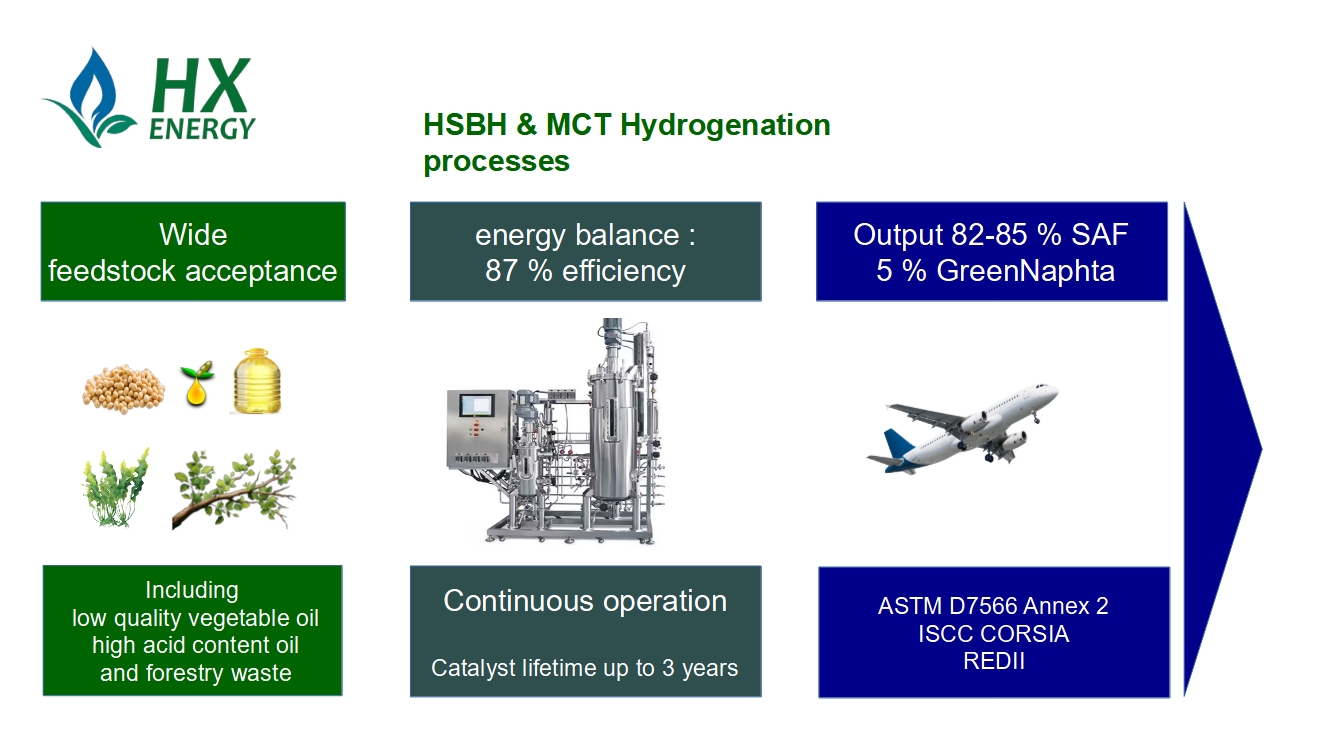

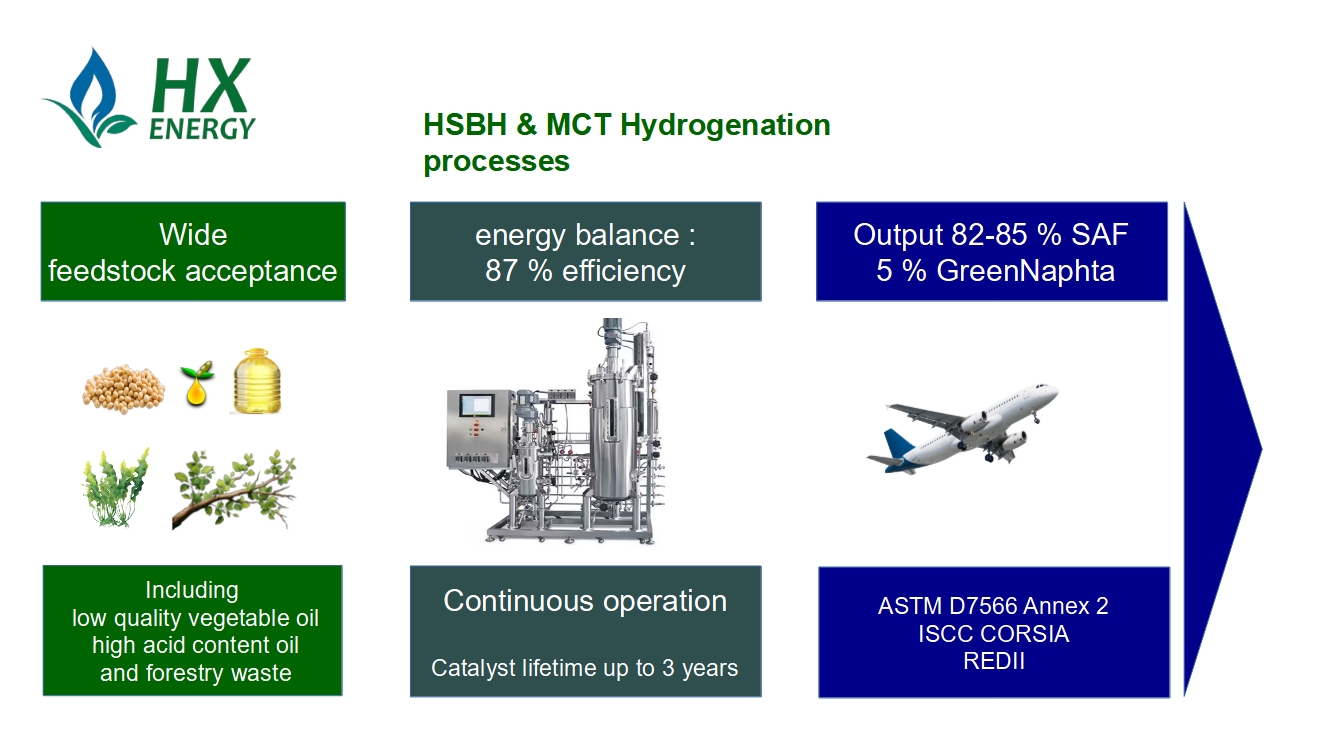

The company deploys advanced hydrogenation and hydroprocessing technologies,

combining suspended-bed hydrogenation (HSBH / MCT) with fixed-bed hydrotreating,

hydrocracking, and isomerization units, in hybrid configurations adapted to

feedstock quality and product targets.

This approach enables the industrial processing of advanced and non-conventional

feedstocks, beyond standard vegetable oils, while ensuring stable operation,

certification compliance, and bankable project economics.

R&D

With internal applied R&D and process engineering capabilities, supported by

technology partners such as Haixin, and an engineering and R&D center based

in Qingdao (SCODA area) operating with a multinational team, HXELAB delivers

execution-oriented, industrial solutions for the large-scale deployment of

SAF and renewable diesel.

Catalysts

Our company works in partnership with Beijing Haixin Energy Technology group to

offer adsorbents, hydrogenation catalysts

and precious metal catalysts.

Building the future : Green Enzymatic BioChemistry

The HX Energy Labs are committed to driving innovation

in the field of green chemistry. Our team is actively

engaged in

developing new pathways to optimise the valorisation

of proteins, lipids and carbohydrates present in

advanced vegetables.

Enzymatic processing represents a promising avenue

for transforming advanced feedstock into biofuels.

- Low energy consumption along the pathway

- Valorization of side products

- Accurate selection of molecules

Building the future : Advanced feedstock production

The HX Energy Labs explore advanced feedstock

production, including camelina, pongamia, brassica

carinata, algae, and others.

We are working with OLILAB, a company specialising in

water reclamation technologies and advanced farming,

including IMTA and IMTF facilities, to design and build

farming and aquaculture projects in Asia, Latin America

and Australia. and aquaculture projects in Asia,

Latin America and and Central Asia.